Water Fit

PRODCUTS

Quality Products & Professional Services in the field of Water Supply.

PRODUCTS

- HDPE pipes and fittings

- UPVC pipes and fittings

- Rigid and flexible Conduits

- Irrigation line and accessories

- PPR pipes and fittings

- Galvanized pipes and fittings

- Steel pipe and fittings

- Gardening accessories

- Water proof membrane

- G-Tex Membrane

- Industrial Valves and fittings

- Butt Welding Installation for HDPE pipes Plastic Raw Materials

HDPE PIPES

HDPE Pipes, which stands for High-Density Polyethylene pipes, are a popular choice for plumbing and various industrial applications. They are known for their numerous advantages over traditional pipe materials like metal or concrete. Here’s a breakdown of HDPE pipes and what sets them apart:

HDPE Pipes: A Durable and Versatile Choice

- Material: Made from high-density polyethylene, a strong and non-corrosive plastic.

- Durability: Highly resistant to impacts, chemicals, and harsh environments.

- Flexibility: Can bend to accommodate uneven surfaces, reducing the need for fittings.

- Lightweight: Easier to transport and handle compared to metal pipes.

- Leak-proof connections: Joined using heat fusion methods, creating strong and leak-free seals.

- Corrosion resistant: Unlike metal pipes, HDPE is immune to rust and corrosion, ensuring a longer lifespan.

- Freeze resistance: Can withstand freezing temperatures without cracking.

PPR PIPES

PPR Pipes, which stands for Polypropylene Random Copolymer pipes, are a type of plastic piping system commonly used in plumbing and hot and cold-water applications. They offer several advantages over traditional pipe materials like metal or even other plastics, making them a popular choice in residential and commercial buildings.

- Material: PPR is a specific type of polypropylene plastic known for its good balance of strength and flexibility.

- Durability: PPR pipes are resistant to corrosion, scaling, and chemicals commonly found in water.

- Heat resistance: They can withstand high temperatures, typically up to 95°C (203°F), making them suitable for hot water lines.

- Lightweight and easy to install: Compared to metal pipes, PPR is lighter and requires less complex connection methods like heat fusion, making installation faster and easier.

- Leak-proof connections: Heat fusion creates strong and permanent joints, minimizing the risk of leaks.

- Good flow characteristics: The smooth internal surface of PPR pipes reduces friction, allowing for better water flow compared to rougher materials.

- Recyclable: PPR is an eco-friendly option as it can be recycled at the end of its lifespan.

UPVC PIPES

UPVC Pipes, which stands for Unplasticized Polyvinyl Chloride pipes, are a widely used type of plastic pipe known for their affordability, durability, and ease of installation. They are a common choice for various plumbing and non-pressurized applications. Here’s a breakdown of UPVC pipes and how they compare to other options:

UPVC Pipes: A Versatile and Cost-Effective Choice

- Material: UPVC is a rigid plastic made from PVC (polyvinyl chloride) without added plasticizers, making it stronger and more resistant to heat than standard PVC.

- Durability: UPVC pipes are resistant to corrosion, chemicals, and impacts, ensuring a long lifespan.

- Lightweight: Easier to transport and handle compared to metal pipes.

- Leak-proof connections: Solvent cement or mechanical couplings create secure joints.

- Cost-effective: Generally, less expensive than metal pipes or some other plastic options.

- Easy to install: UPVC pipes can be cut and glued or joined with mechanical fittings, making installation relatively simple.

- Good electrical insulation: UPVC is non-conductive, making it suitable for electrical applications.

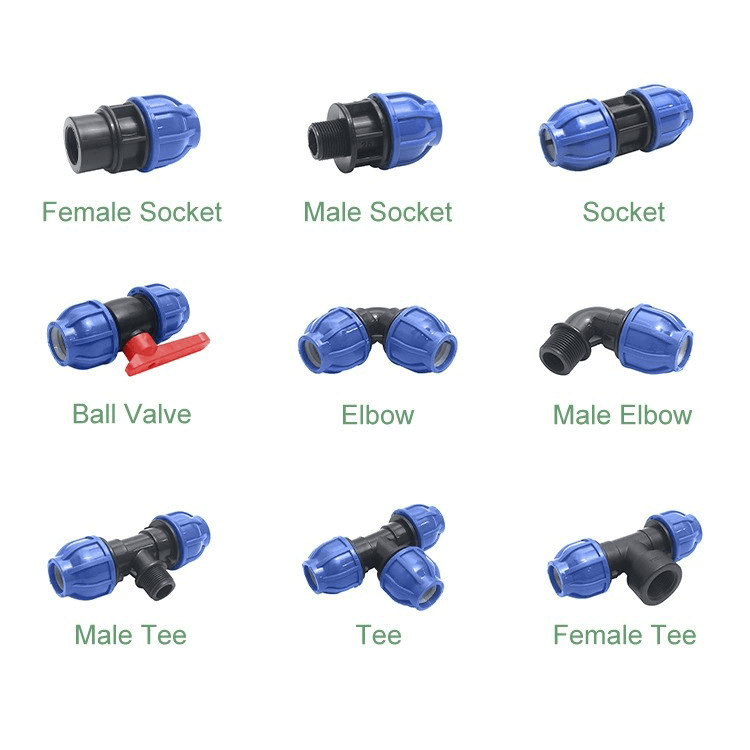

HDPE PIPE FITTINGS

HDPE Pipe Fittings, short for High-Density Polyethylene pipe fittings, are essential components for connecting and joining HDPE pipes to create a complete piping system. Unlike traditional metal fittings that require threading or welding, HDPE fittings are designed for a smoother and more efficient installation process.

Applications of HDPE Pipe Fittings:

- Potable water supply: HDPE is safe for transporting drinking water.

- Sewerage systems: Durable and resistant to corrosion from wastewater.

- Gas distribution: Can be used for both low and high-pressure gas lines.

- Irrigational systems: Ideal for agricultural applications due to their ease of use and durability.

- Electrical and communication conduits: Protect cables and wires underground or aboveground.

- Industrial applications: Used in various industrial settings for transporting chemicals, slurries, and other fluids.

PPR PIPE FITTINGS

PPR pipe fittings, short for Polypropylene Random Copolymer pipe fittings, are crucial components for building a complete PPR piping system used for hot and cold-water distribution. These fittings connect PPR pipes efficiently, creating a watertight and long-lasting network. Here’s a closer look at PPR pipe fittings:

Applications of PPR Pipe Fittings:

- Hot and cold-water supply: A popular choice for both hot and cold-water distribution in residential and commercial plumbing systems.

- Domestic water systems: Can be used for various purposes like washing machines, dishwashers, and faucets.

- Radiant heating systems: PPR’s heat resistance makes it suitable for low-temperature radiant floor heating applications. (Double-check temperature limitations for specific systems.)

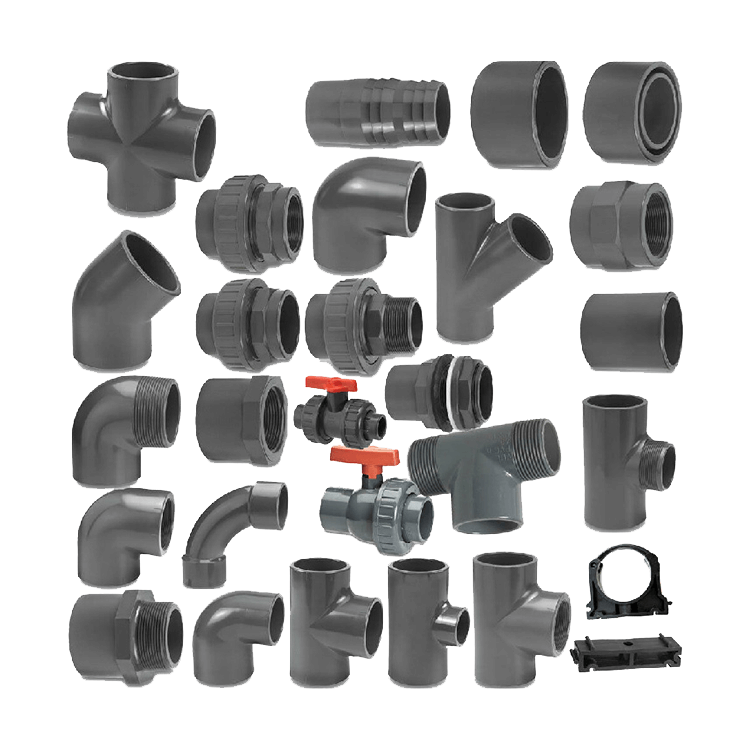

UPVC PIPE FITTINGS

UPVC pipe fittings are essential components for building a complete UPVC piping system, commonly used for non-pressurized applications like drainage, irrigation, and cold-water supply. These fittings connect UPVC pipes efficiently, creating a leak-proof and long-lasting network.

Applications of UPVC Pipe Fittings:

- Drainage systems: A popular choice for waste disposal due to their durability, chemical resistance, and ease of installation.

- Sewage systems: Can be used for non-pressurized waste lines (check local building codes).

- Irrigation systems: Commonly used for non-pressurized irrigation systems in gardens and landscaping.

- Cold water supply: In some cases, UPVC may be used for cold water supply, but local building codes may have restrictions due to potential leaching concerns.

- Electrical conduits: UPVC’s non-conductive nature makes it suitable for protecting electrical wires and cables underground or aboveground (for low voltage applications).

RIGID & FLEXIBLE CONDUITS

Conduits are tubes that are used to protect electrical wires and cables. They come in two main varieties: rigid and flexible. Rigid conduit is made from a hard plastic material, typically PVC (polyvinyl chloride) whereas Flexible conduit is made from a softer plastic material, such as PVC with plasticizers added.

The best type of conduit for a particular application will depend on the specific requirements of the project. Here are some factors to consider:

- Durability: Rigid conduit is more durable than flexible conduit.

- Ease of installation: Flexible conduit is easier to install than rigid conduit.

- Environmental conditions: Rigid conduit is a better choice for exposed runs and harsh environments.

- Cost: Rigid conduit is typically less expensive than flexible conduit.

- Maintenance: Both types of conduits require minimal maintenance.

IRRIGATION LINE & ACCESSORIES

Irrigation lines and accessories are essential components for setting up a drip irrigation system. Unlike traditional sprinklers that spray water everywhere, drip irrigation delivers water directly to the root zone of plants, which conserves water and reduces weed growth.

Irrigation Lines

- Plastic irrigation lines are thin tubes, typically made of high-density polyethylene (HDPE) or low-density polyethylene (LDPE), that deliver water to plants.

- They come in various diameters, ranging from 1/4 inch to 1 inch, with 1/4 inch being the most common for home gardens.

- These lines are usually sold in rolls of 100 feet to 1,000 feet.

Irrigation Accessories

There are a wide variety of plastic irrigation accessories available to help you customize your drip irrigation system to your specific needs.

GALVANIZED PIPES & FITTINGS

Galvanized pipes and fittings are a type of plumbing system that uses zinc-coated steel pipes for transporting water, gas, and other fluids

The zinc coating, called galvanization, helps to protect the steel pipe from rust and corrosion. Galvanized pipes were once the most common type of pipe used in plumbing, but they have become less popular in recent years due to concerns about the health effects of lead that can leach from the zinc coating over time.

WATER PROOF MEMBRANE

Waterproof membranes are basically shields that protect structures from water infiltration. They come in various forms like sheets or liquids, and are applied to surfaces like foundations, roofs, walls, and basements. Here’s a breakdown of their key features:

- Function: Their primary function is to block water entry, acting as a barrier against leaks and seepage. This protects the building elements from water damage, which can lead to structural issues, mold growth, and other problems.

- Types: There are two main types: sheet membranes and liquid membranes. Sheet membranes are pre-formed materials like plastic or rubber sheets, while liquid membranes are paint-on or trowel-on coatings.

- Materials: They are typically made from waterproof materials like rubber, plastic, bitumen, or special coatings. The chosen material depends on factors like flexibility, durability, and intended use.

By creating a waterproof barrier, membranes play a crucial role in maintaining the integrity and longevity of a building.

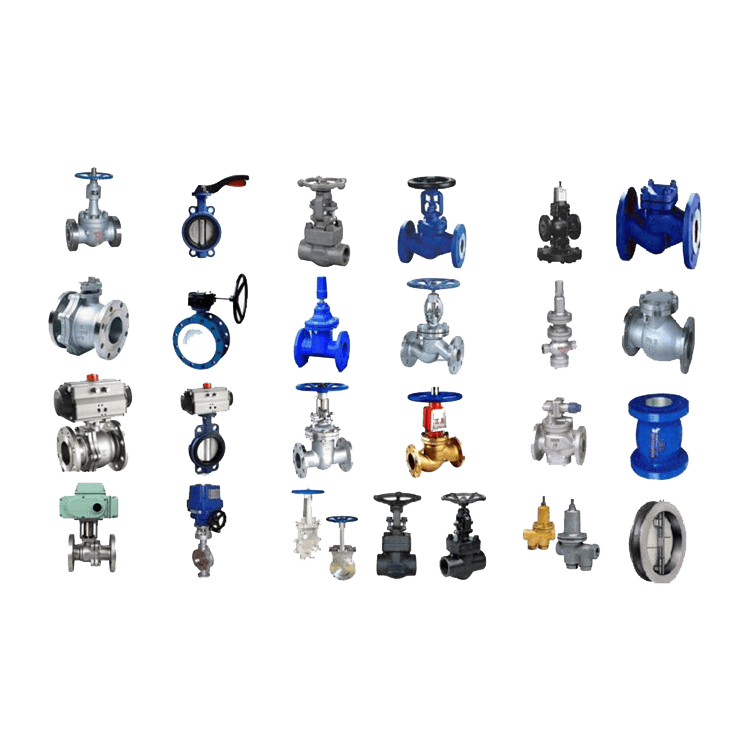

INDUSTRIAL VALVES & OTHER ACCESSORIES

Industrial valves are mechanical devices that control the flow, pressure, and direction of fluids and gases within a process in various industries. They play a critical role in managing these fluids and gases safely and efficiently. The proper selection and use of industrial valves are crucial for ensuring the safe and efficient operation of various industrial processes.

Their primary function is to regulate fluid flow. This can involve turning the flow on or off completely, regulating the flow rate, or changing the direction of flow.

Our comprehensive selection of specialized accessories caters to a wide range of applications, from water systems to petrochemical processes. With an extensive array of plastic and metal valves and components, we provide the essential tools for optimizing fluid flow in various industries.

DOUBLE WALL CORRUGATED PIPES

Double wall corrugated pipes (DWC pipes) are a type of pipe consisting of two layers, as the name suggests. They are typically made of high-density polyethylene (HDPE).

- Advantages: DWC pipes offer several advantages over traditional options like concrete or metal pipes:

- Corrosion and abrasion resistant: HDPE material resists rust, chemicals, and erosion.

- Hydraulically efficient: Smooth interior allows for smooth flow with minimal friction loss.

- Lightweight: Easier to transport and handle compared to heavier concrete pipes.

- Strong and flexible: Corrugated design offers good load-bearing capacity and can handle some ground movement.

- Easy installation: Typically come in long lengths with easy jointing systems, reducing installation time and cost.

Overall, double wall corrugated pipes are a versatile and reliable option for various drainage and sanitation applications.

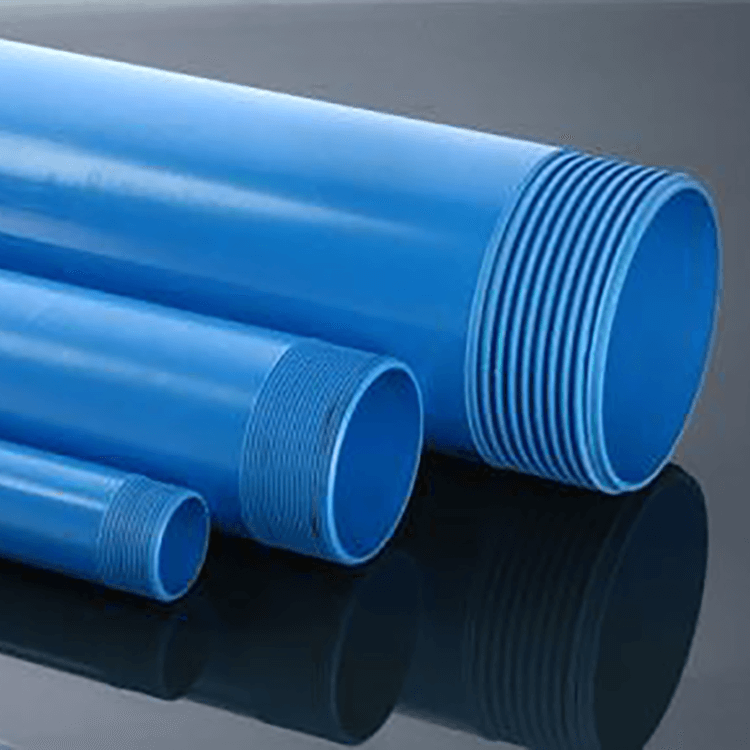

PVC CASING

PVC casings are tubes made from polyvinyl chloride, a common and versatile plastic material. Here are some of the common applications for PVC casings:

- Water Wells: PVC is a popular choice for well casings due to its affordability, corrosion resistance, and ease of installation. It keeps the wellbore stable and prevents contamination from surrounding soil and water.

- Underground Conduits: PVC casings are used to protect and route electrical wires, fiber optic cables, and other utilities underground. They shield the cables from damage and moisture.

- Drainage Systems: PVC pipes are commonly used for drainage applications due to their light weight, easy installation, and smooth flow properties. They can be used for storm water drainage, septic systems, and agricultural drainage.

- Sewer Lines: PVC’s chemical resistance and affordability make it a suitable material for sewer lines, conveying wastewater away from homes and buildings.

It’s important to note that PVC casings may not be suitable for all applications, particularly those involving high pressure or extreme temperatures. Consulting a professional is recommended to determine the right material for your specific project needs.

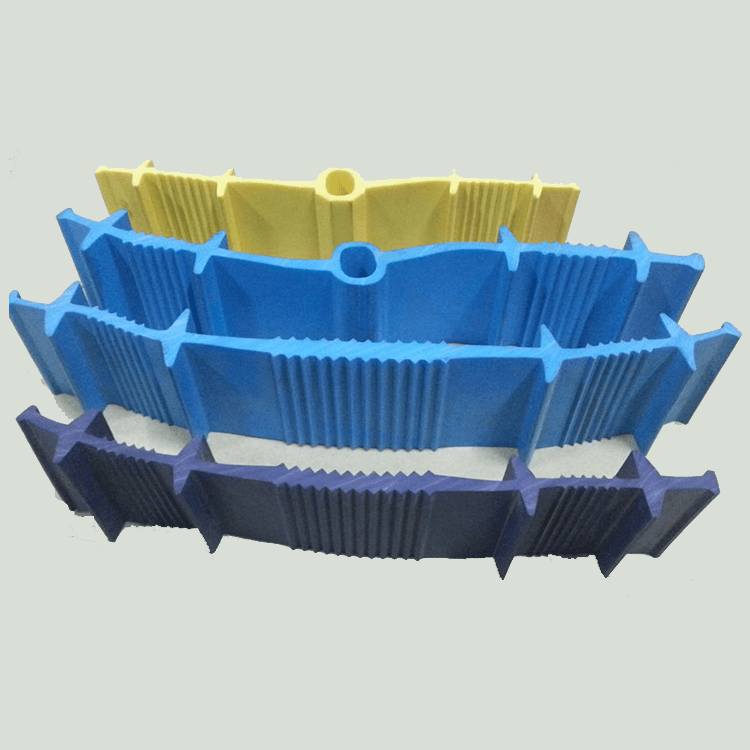

Water Stopper

Plastic water stoppers, also sometimes called PVC water stoppers, are waterproofing elements used in concrete construction. They are typically made of polyvinyl chloride (PVC), a strong and flexible plastic material that resists corrosion.

- Advantages: Plastic water stoppers offer several benefits over traditional methods like pouring additional sealant:

- Effective waterproofing: They create a continuous barrier against water leakage.

- Accommodates movement: The flexible design allows for some movement in the concrete joints without compromising the seal.

- Durable and corrosion-resistant: PVC material withstands harsh conditions and resists degradation.

- Cost-effective: Provide a reliable waterproofing solution at a relatively lower cost compared to some other methods.

Overall, plastic water stoppers are a vital component in ensuring the watertight integrity of concrete structures, preventing leaks and protecting the structural elements from water damage.

RAW MATERIALS

PE 100 HDPE Plastic Granules are a versatile and high-performance plastic material used in various demanding applications due to their strength, durability, and chemical resistance. PE 100 HDPE Plastic Granules are a type of plastic material used in a variety of applications. Here’s a breakdown of the key terms:

- PE 100: This refers to a specific grade of High-Density Polyethylene (HDPE). PE 100 is known for its high strength, stiffness, and resistance to cracks compared to other HDPE grades.

- HDPE (High-Density Polyethylene): This is a common thermoplastic known for its durability, chemical resistance, and recyclability. It’s widely used across various industries.

- Granules: These are small, pellet-shaped particles of the plastic material. HDPE plastic is typically sold in granule form for ease of transportation and processing.